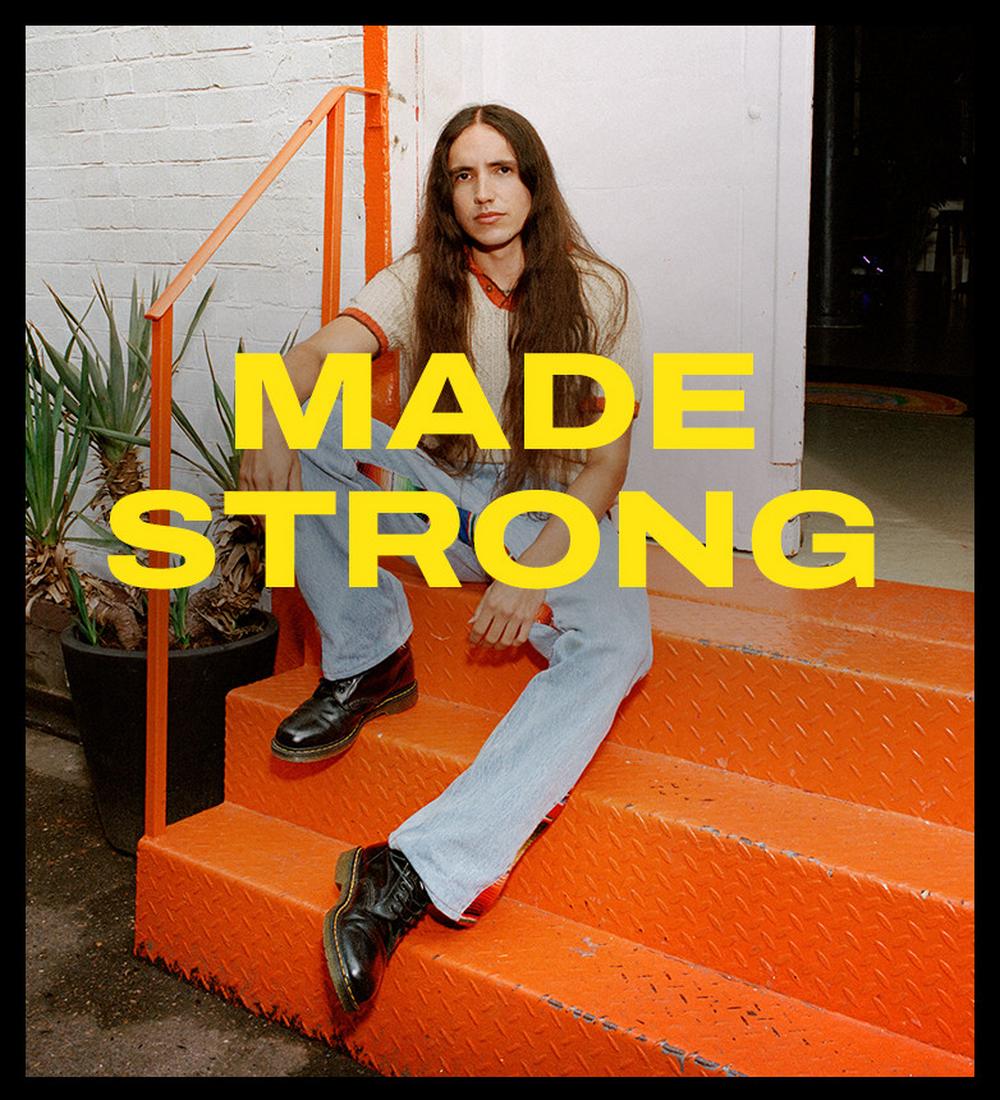

Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960

ce 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960

BEING

RESPONSIBLE

BOOTMAKERS

At Dr. Martens, we believe the most responsible thing we can do as a bootmaker is to maximise the longevity of each pair through the creation of timeless, hardwearing, repairable footwear. At the same time, we have a duty to consider the impact our business has on both people and the planet, which we take incredibly seriously. Below, you can discover more about our approach and ambitions.

BEING

RESPONSIBLE

BOOTMAKERS

At Dr. Martens, we believe the most responsible thing we can do as a bootmaker is to maximise the longevity of each pair through the creation of timeless, hardwearing, repairable footwear. At the same time, we have a duty to consider the impact our business has on both people and the planet, which we take incredibly seriously. Below, you can discover more about our approach and ambitions.

OUR

ORIGINS

OUR

ORIGINS

OUR SHOEMAKING HERITAGE WAS CENTERED AROUND CREATING TIMELESS FOOTWEAR WITH A DISTINCTIVE DESIGN, FUNCTIONAL BENEFITS AND LONG-LASTING DURABILITY.

Based on the Griggs family business’ legacy of quality footwear and the progressive outsole creations of Dr. Klaus Maertens and Dr. Herbert Funck. Our manufacturing heritage lays the foundation upon which our modern products are built.

TIMELESS

DESIGN

Our classic silhouettes are designed to be worn season after season and passed down from generation to generation. Each element carefully chosen to create the distinctive design language of Dr. Martens. From our AirWair heel loop to the grooved outsole to our standout yellow welt stitch.

DURABLE

CONSTRUCTION

Decades of Griggs family manufacturing expertise combined with German technical innovation and resulted in the creation of the 1460 boot. From the long-lasting and repairable Goodyear welted and heat-sealed outsole to the uppers secured with our distinctive and extra strong Puritan stitching, Dr. Martens has produced timeless, durable products to maximise longevity for over 60 years.

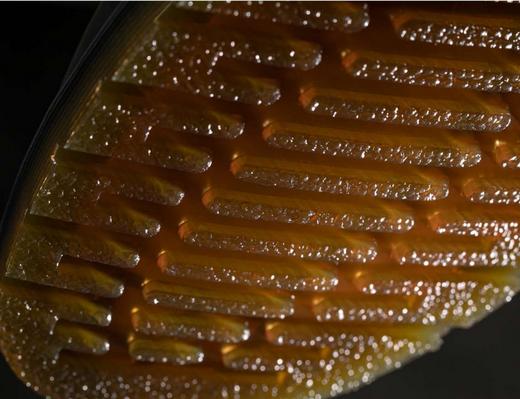

MATERIALS

MATTER

Quality materials are central to our production of long-lasting footwear and have been since the very beginning. Leather has been used on Dr. Martens footwear for over 60 years due to its characteristics of durability, flexibility, versatility and breathability, which makes it particularly good for shoemaking. Our air cushioned outsoles made from PVC are used on the majority of our footwear products. They provide a great mix of comfort, durability and repairability. At DM’s, any alternative to leather or PVC must meet our high durability standards to be considered.

CARE AND REPAIR

One of the additional benefits of Dr. Martens approach to our original designs, particularly the Goodyear welt stitch combined with the PVC outsole, is that it makes our footwear practical and repairable. Historically, each pair would come with instructions on how to do basic repairs at home with a hot knife (which is something we explicitly do not recommend today for safety reasons). Leather, when properly maintained, can be worn for years and years which is why we offer an extensive range of shoe care products.

CARE AND REPAIR

One of the additional benefits of Dr. Martens approach to our original designs, particularly the Goodyear welt stitch combined with the PVC outsole, is that it makes our footwear practical and repairable. Historically, each pair would come with instructions on how to do basic repairs at home with a hot knife (which is something we explicitly do not recommend today for safety reasons). Leather, when properly maintained, can be worn for years and years which is why we offer an extensive range of shoe care products.

ONGOING

PROJECTS

ONGOING

PROJECTS

We’ve never been a company to stand still. Here are some of the latest strides we’ve made to make us a more responsible company and to keep each pair of Dr. Martens boots and shoes going for longer.

REPAIR

SERVICE

We’ve recently partnered with The Boot Repair Co. in the UK to offer a pilot program for authorised repair of DM’s footwear and accessories. Through this service, we use the same quality of materials to breathe new life into old footwear and keep them going for longer. Watch this space to see how we expand this service in the future.

PRE-LOVED

FOOTWEAR

For many of our wearers their first pair are pre-loved, passed down from friends and family or bought on the second-hand market. In the UK we launched our first official second-hand store via Depop. We restore worn boots and shoes to their former glory and maximise their lifespan. If successful, we want to make this service available outside of the UK.

SELECTING

BETTER MATERIALS

We continue to adopt new opportunities to reduce the impact of the materials we use. Some examples of the changes we’ve made include using 100% recycled materials in our classic heel loops, removing 25% of the materials used in our standard shoeboxes, and committing to sourcing all our leather from Leather Working Group certified tanneries.

THE

FUTURE

THE

FUTURE

WE HAVE BOTH LONG AND SHORT-TERM GOALS AND AMBITIONS TO CONTINUE OUR IMPROVEMENTS WITHOUT FORGETTING ABOUT OUR ORIGINS OR LETTING PERFECT GET IN THE WAY OF PROGRESS. BELOW IS A SNAPSHOT OF WHAT WE HAVE PLANNED.

NEW

MATERIALS

We’re currently exploring new materials that meet our high durability standards whilst reducing our impact on the planet. This includes identifying sources that limit the impact of our leather, as well as innovating with new alternative materials. Genix Nappa is our latest progressive material created from waste leather offcuts.

Looking ahead we’re committed to utilising a sustainable vegan upper material by 2028 and a sustainable alternative to our PVC outsoles by 2035. By 2040 we aim to have 100% of our footwear made from sustainable materials, 100% of our products to have a sustainable end-of-life option and 100% of the natural materials used in products to be sourced from regenerative agriculture. These actions will guide us to becoming a net-zero business by 2040. The full list of our goals can be found here.