Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960

ce 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960

Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960

ce 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960

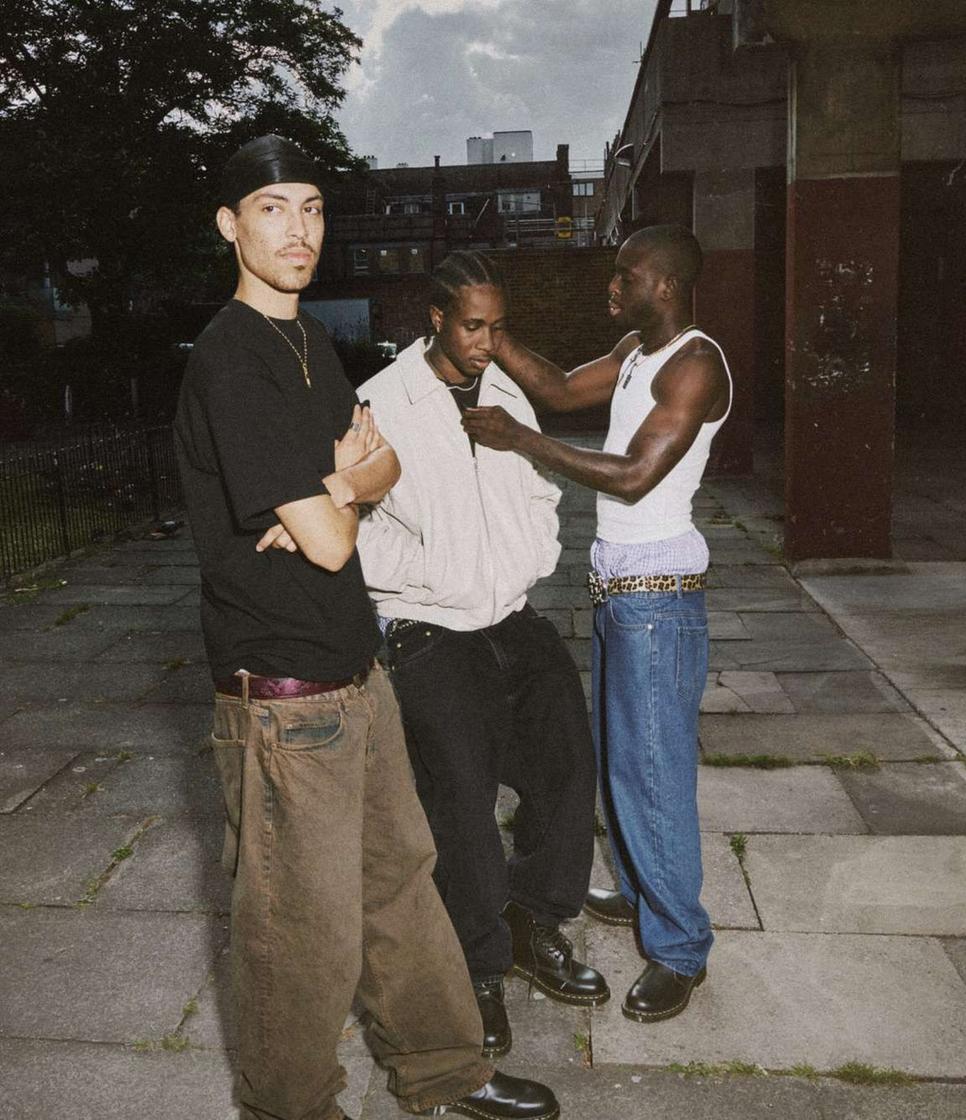

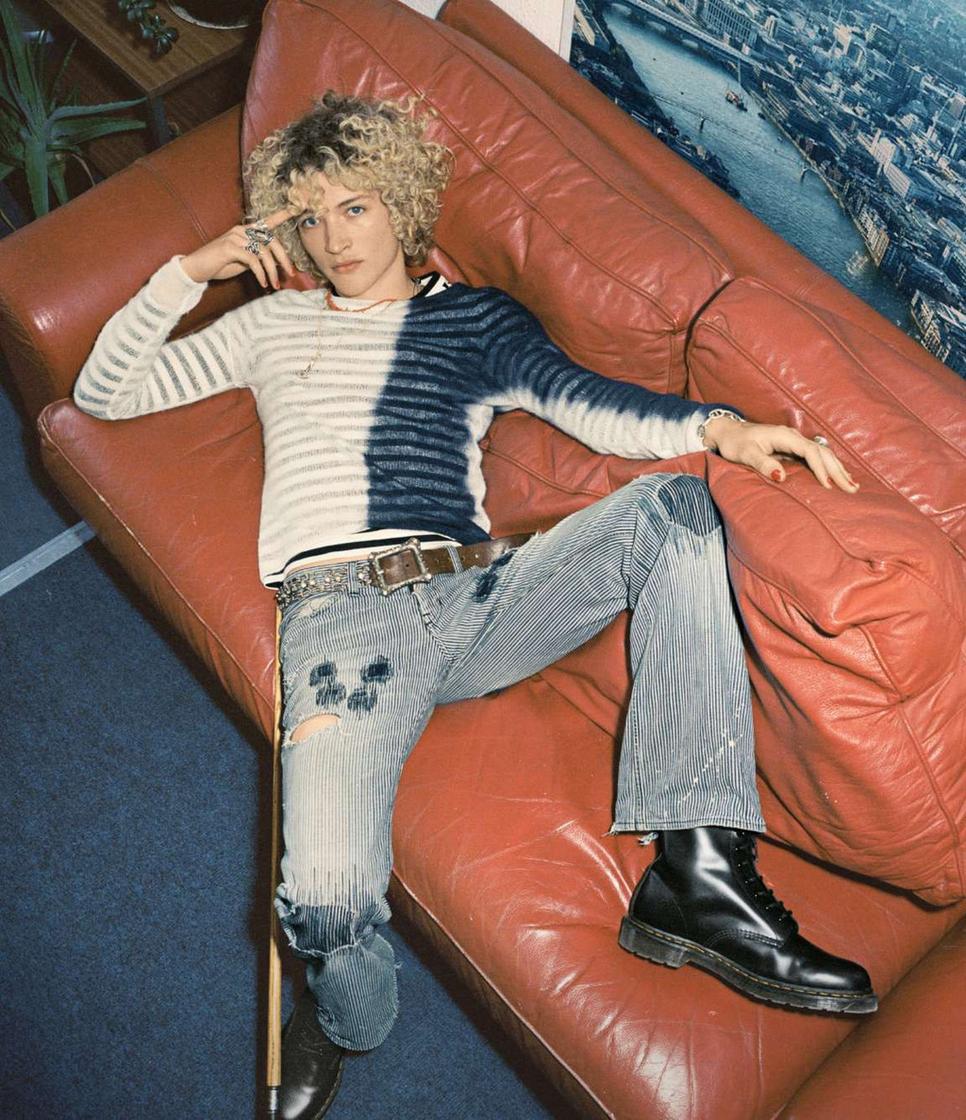

New generation. New definitions

NIKO

(she/her)

Niko is a California-based first-generation Mexican singer-songwriter who incorporates English and Spanish into her lyrics to own her heritage and represent her culture. Niko’s music is a way for her to tell her unique story and the stories of people who look like her without worrying about how she compares to other artists.

“

The most important thing that you can do is be true to yourself.

That’s what’s going to make you strong.

”

New generation. New definitions

NIKO

(she/her)

Niko is a California-based first-generation Mexican singer-songwriter who incorporates English and Spanish into her lyrics to own her heritage and represent her culture. Niko’s music is a way for her to tell her unique story and the stories of people who look like her without worrying about how she compares to other artists.

“

The most important thing that you can do is be true to yourself.

That’s what’s going to make you strong.

”

Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960

ce 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960

Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960

ce 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960 Made Strong Since 1960

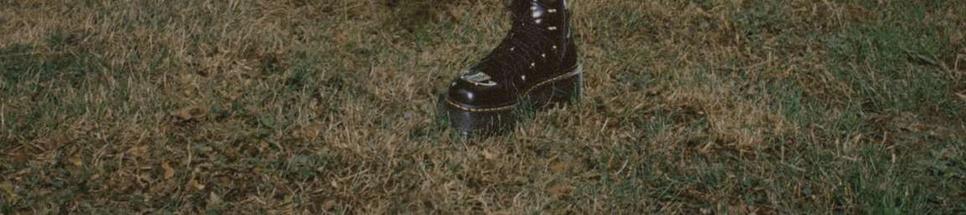

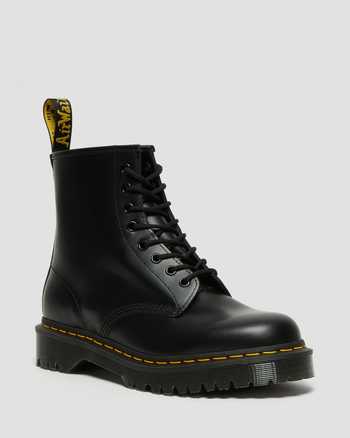

Make them yours

Make them

even stronger

Well-worn or box fresh. Every pair needs some care from time to time. Find out how to make sure your boots and shoes can keep pace with wherever life takes you.

Make them yours

Make them

even stronger

Well-worn or box fresh. Every pair needs some care from time to time. Find out how to make sure your boots and shoes can keep pace with wherever life takes you.

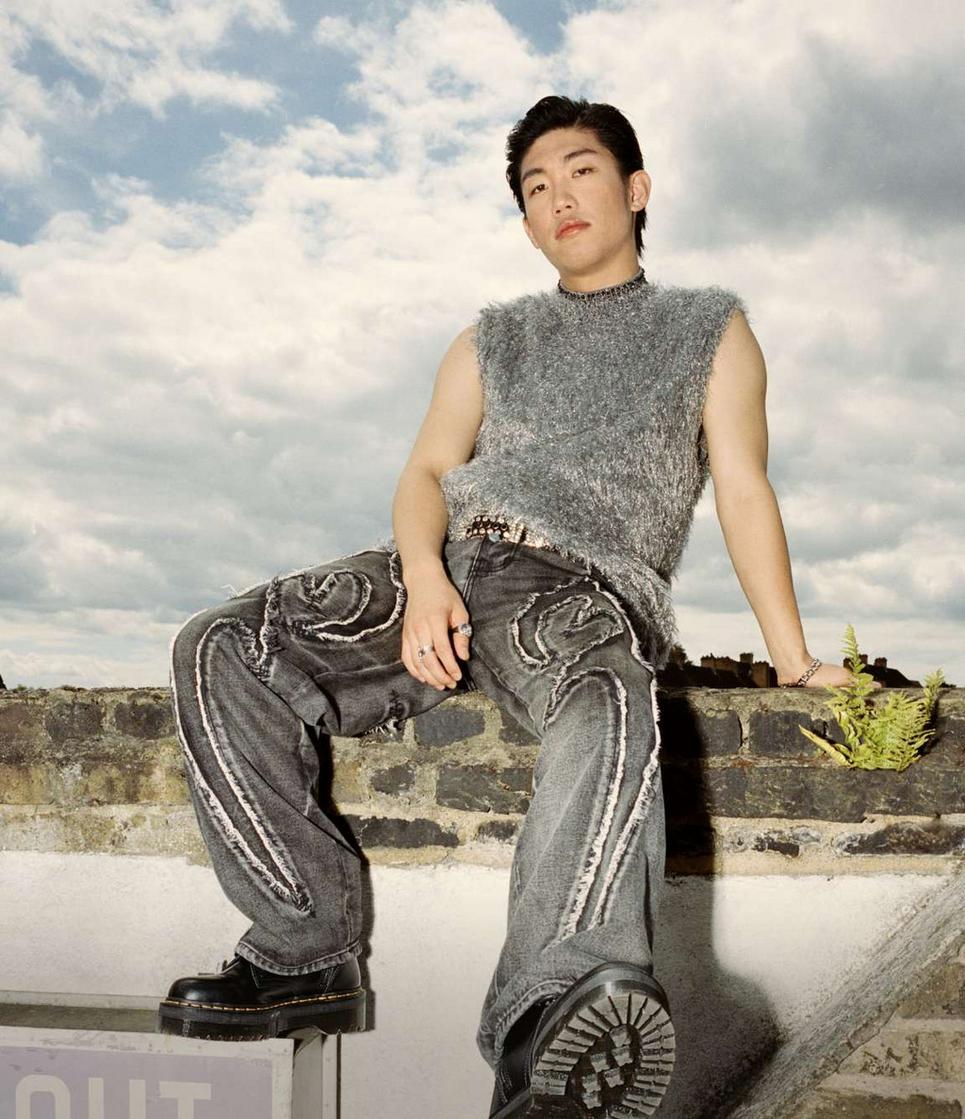

Feel good

from the first step

It’s no secret our boots and shoes need time to break in. But there are things you can do to ease into your first few steps. Check out our tips and tricks so you can walk out with confidence.

Find out

what we’re made of

Smooth, soft, or shiny. Whatever your statement, there’s a durable DM’s leather to suit every wear. Check out our leather guide to learn out more.